JVN BEARINGS

Shop No F6, 1st Floor,

Ruby Commercial Centre,

Pumpwell, Mangalore, Karnataka.

+91- 8244052261

Introduction to Bearings

What are Bearings?

A bearing is a machine element that constrains relative motion and is used to reduce friction between moving parts of a machine to obtain the desired motion. For example, A load of a rotating fan is supported by a bearing while reducing noise and vibration and restricting the movement to a radial axis.

The main functions of bearings are:

- To reduce friction between moving rotatory parts.

- To support rotating parts of a machine.

- To bear radial and thrust load.

How do Bearings Work?

- Bearings typically have to deal with two kinds of loading, radial, and thrust/axial loads.

- Radial load is the load acting perpendicular to the longitudinal axis. Ex: Fans, Cycles, SkateBoards, Mixers / Food Processors, etc.

- Axial or Thrust load is the load acting parallel to the longitudinal axis. Ex: Bar Stools, Rotating Tables, Screw Jacks, Fluid Control Valves, etc

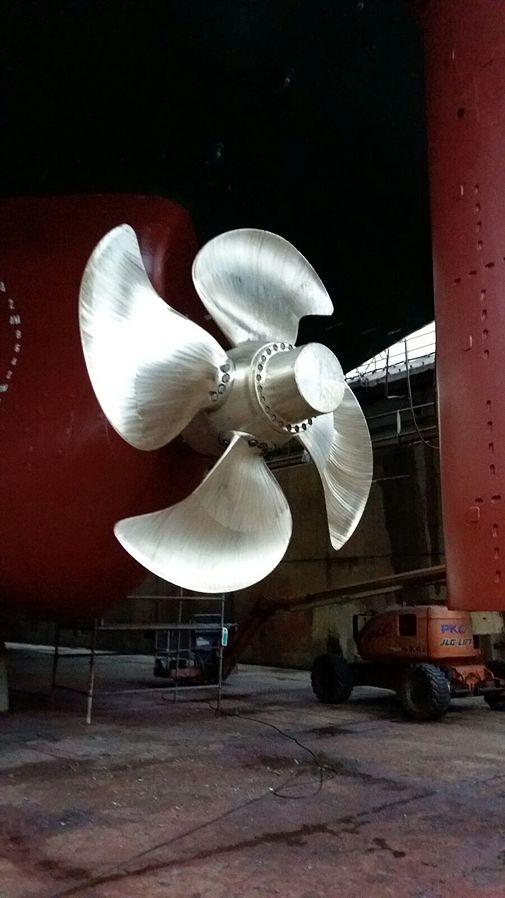

- The Combined load is the load acting both parallel and perpendicular to the longitudinal axis. Ex: Agriculture Equipment, Gearboxes and axles, engines and reducers, propellers, railroad axles, and mining and construction equipment.

- Depending on where the bearing is being used, it may handle radial loading, thrust loading or a combination of both.

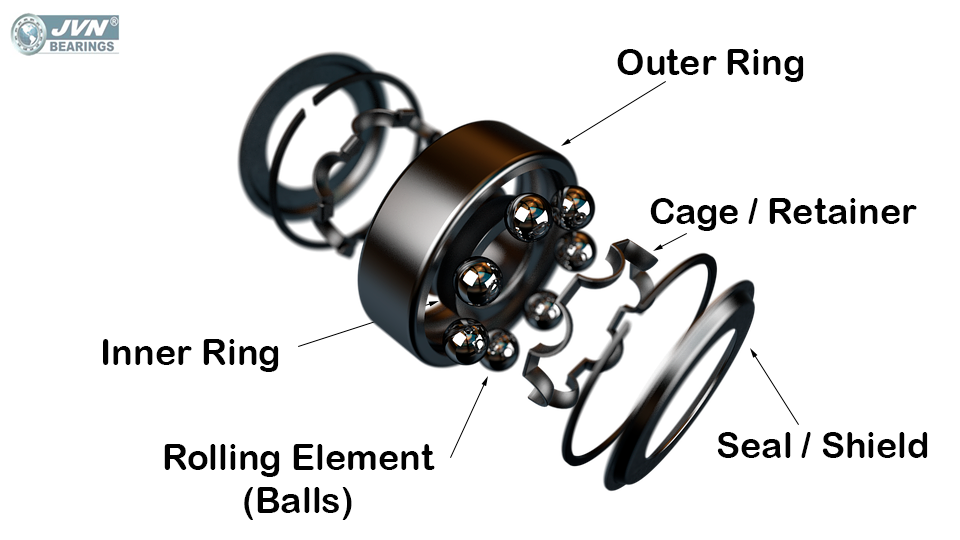

Components / Parts of a Standard Bearing

The standard essential components of a bearing are as follows:

- Inner Ring:

The Inner Ring is the smaller of the two bearing rings. It has a groove on its outer diameter to form a raceway for the balls. The surface of outside diameter path is finished to extremely tight tolerances and is honed to be a very smooth surface. The inner ring is mounted on the shaft and it is the rotating element. - Outer Ring:

The Outer Ring is the larger of the two bearing rings. On outer ring, there is a groove on its inside diameter to form a pathway for the balls. It also has the same high precision finish of the inner ring. The outer ring is usually held stationery. - Rolling Element: (Balls, Cylindrical Rollers, Spherical Rollers, Tapered Rollers, Needle Rollers):

The rolling elements separate the inner ring and outer ring and permit the bearing to rotate with minimal friction. The dimension of the rolling elements is made slightly smaller than the track on the inner and outer rings. Rolling element dimensions are controlled to very high accuracy. Surface finish and size variations are important attributes. These attributes are controlled to a micro inch level. - Cage (Retainer):

The purpose of the cage in bearings is to separate the rolling elements, maintaining a constant spacing between the inner and outer rings, to accurately guide the rolling elements in the path during rotation and to prevent the rolling elements from falling out. - Lubrication:

The lubricant is an integral part of a bearing’s standard components. Lubrication is added to reduce friction losses in bearing between inner and outer rings. - Other Optional Bearing components:

The other additional components shields and seals enhance the performance and life of the ball bearing. These optional components are added to the bearing as per the customer requirement to increase the performance of the bearing.

Shields:

The shield is a stamped, profiled sheet metal disc. Shield is pressed into a very small groove on the inside edge diameter of the outer ring. A small space or gap remains open between the outside diameter of the inner ring and shield. Because the shield does not contact the inner ring of the bearing, there is no added friction between the shield and bearing. This results in a bearing that hasa very low torque. Purpose of shields is to keep larger particles of contamination from entering the bearing.

Seals:

The seal is also inserted into the very small groove on the inside, edge diameter of the outer ring. The inner edge of the seal ismoulded into a specifically designed lip configuration.