JVN Bearings, Shop No F6,

1st Floor, Ruby Commercial Centre,

Mangalore, 575002

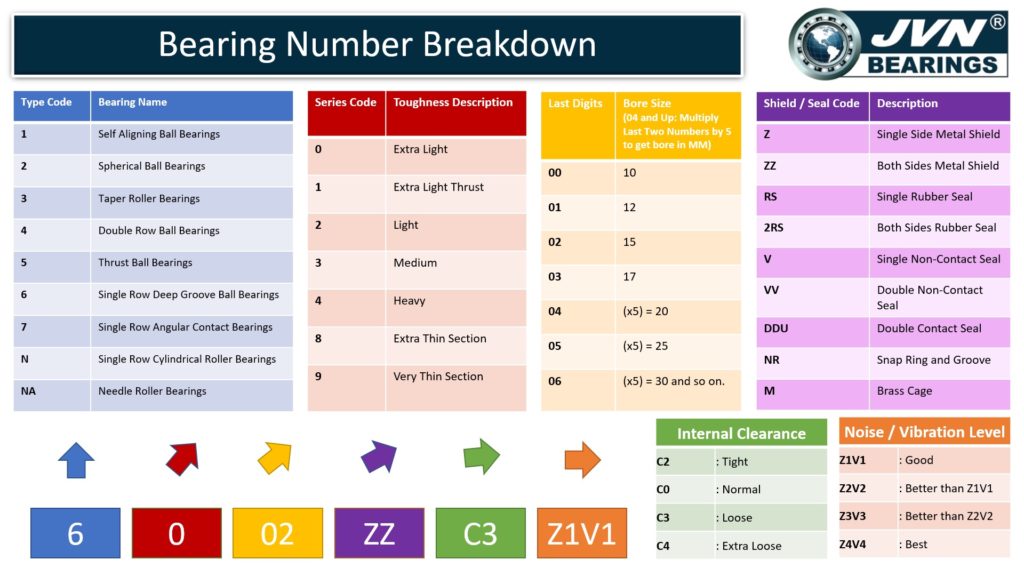

Bearing numbers can seem very confusing and random to the average person. But there is a system to all the madness!

There are several numbering systems used in the bearing industry today. The boundary dimensions for certain series of bearings are defined in various standards, such as ABMA, JIS and ISO. (Learn more about them here.) In addition, many manufacturers have created their own numbering systems that are a combination of the bearing numbers and a series of codes that define additional specifications.

How to Identify Bearings by their Numbers?

Number Breakdown:

- Types of Bearings

- Series Description

- Bore Size of Bearings

- Shield / Seal Configuration

- Internal Clearance

- Noise and Vibration

Types of Bearings

| Type Code | Bearing Name |

| 1 | Self Aligning Ball Bearings |

| 2 | Spherical Ball Bearings |

| 3 | Taper Roller Bearings |

| 4 | Double Row Ball Bearings |

| 5 | Thrust Ball Bearings |

| 6 | Single Row Deep Groove Ball Bearings |

| 7 | Single Row Angular Contact Bearings |

| N | Single Row Cylindrical Roller Bearings |

| NA | Needle Roller Bearings |

The first digit of a bearing signifies the type of bearing. For Ex: In a 6208 bearing the first digit being ‘6′ is a Single Row Deep Groove Ball Bearing.

In case of Inch bearings, the bearing’s first digit will be ‘R’. After ‘R’, the size of the bearing will be given in 1/16th of an inch. For Ex: R6-2RS bearing. Here, R6 signifies, it is an inch bearing whose bore size is 6/16th of an inch or 0.375 inches.

Series Description

| Series Code | Toughness Description |

| 0 | Extra Light |

| 1 | Extra Light Thrust |

| 2 | Light |

| 3 | Medium |

| 4 | Heavy |

| 8 | Extra Thin Section |

| 9 | Very Thin Section |

The second digit of a bearing number indicates the Bearing Series which denotes the toughness / strength of the bearing. Bearing strength is the maximum stress load that the unit can “bear” or hold before the structure fails. It can be measured by Tensile Strength, Tensile Elongation, Compressive Strength, Flexural Strength, Modulus and Hardness.

Bore Size of Bearings

| Last Digits | Bore Size (04 and Up: Multiply Last Two Numbers by 5 to get bore in MM) |

| 00 | 10 |

| 01 | 12 |

| 02 | 15 |

| 03 | 17 |

| 04 | (x5) = 20 |

| 05 | (x5) = 25 |

| 06 | (x5) = 30 and so on. |

The third and fourth digit of a bearing number as indicated above refers to the bore size of the bearing. It is the inner diameter of the bearing and is measured in millimeters. From ’00’ to ’03’ the measurements are noted above. From ’04’ onward the bore size is equal to five times the third and forth digit of bearing’s last two numbers.

In case there is no fourth digit, then the 3rd digit indicates the bore size in mm. For Ex: In case of bearing 625 2RS, the bore size of the bearing will be 5mm.

Thus, we can identify now that in case of bearing 6207ZZ, the third and fourth digit ‘07’ means the bearing’s bore size is 35 mm.

Shield / Seal Configuration

| Shield / Seal Code | Description |

| Z | Single Side Metal Shield |

| ZZ | Both Sides Metal Shield |

| RS | Single Rubber Seal |

| 2RS | Both Sides Rubber Seal |

| V | Single Non-Contact Seal |

| VV | Double Non-Contact Seal |

| DDU | Double Contact Seal |

| NR | Snap Ring and Groove |

| M | Brass Cage |

The letters after the bearing number indicates the presence / absence / type of shielding or sealing and any other specialties in the bearing. We can identify now that in case of bearing 6208RS, the last letters ‘RS’ means the bearing is shielded on a single side.

Internal Clearance

| Internal Clearance | |

| C2 | : Tight |

| C0 | : Normal |

| C3 | : Loose |

| C4 | : Extra Loose |

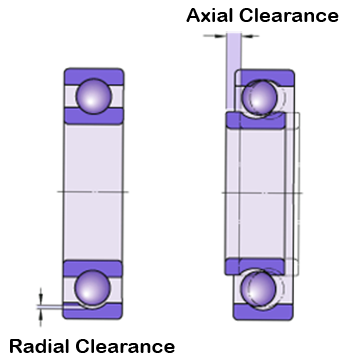

Bearing internal clearance means the total distance through which one bearing ring can be moved in relation to the other in the radial direction (radial internal clearance) or in the axial direction (axial internal clearance).

In almost all applications, the initial clearance in a bearing is greater than its running clearance. The difference is mainly caused by:

- The expansion of the inner ring or the compression of the outer ring reduces the internal clearance.

- Bearings generate heat in operation. Differential thermal expansion of the bearing and mating components influences the internal clearance.

Noise and Vibration

| Noise / Vibration Level | |

| Z1V1 | : Good |

| Z2V2 | : Better than Z1V1 |

| Z3V3 | : Better than Z2V2 |

| Z4V4 | : Best |

Bearing acoustical noise is a function of both (Internal Factors) the bearing itself and (External factors) the way in which it is used. Bearing noise is not generally influenced by ABEC precision, they are independent of precision grades. For Ex. A P6 / ABEC 3 bearing can have a rating of Z2V2 or above. Bearing Noise is affected by the manufacturers’ Internal quality standards with regard to the

- surface finish of the raceways and balls, (through proper grinding, cleaning and dirt free storage)

- roundness of the rings and balls and

- correct cage design.

External factors affecting bearing noise include:

- Lubricant Type,

- Excessive Load,

- Improper Fitting,

- Preload Method,

- Dust Particles and other factors.

The vibration and noise of bearings are classified as four classed as Z1,Z2,Z3 and Z4.It is measured by the instrument of S0910-1.For special requirement, it is measured by BVT-1 and classified as V1, V2, V3 and V4. The classes help consumers select bearings. For Ex: A Z3V3 bearing has an average range of 25-35 dB which is suitable for applications such as in ceiling fans. dB is a measure of volume (loudness of a sound).

| Decibels | Example Source |

| 0 | Silence |

| 20 | Whispering |

| 50 | Relaxed Conversation |

| 80 | Food Processor, Lawn Mower |

| 110 | Rock Concert, Chainsaw |